PRODUCTS & SOLUTIONS

Service for the wheel industry

SPECTROTESTER 1320

- Category : Equipment for wheel industry / VdH

Solutions for Your Application | Wheel Industry

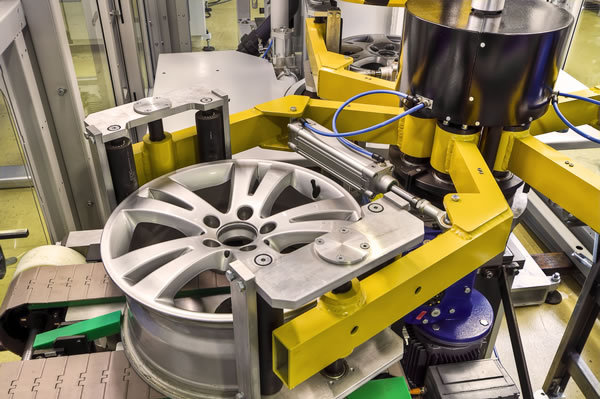

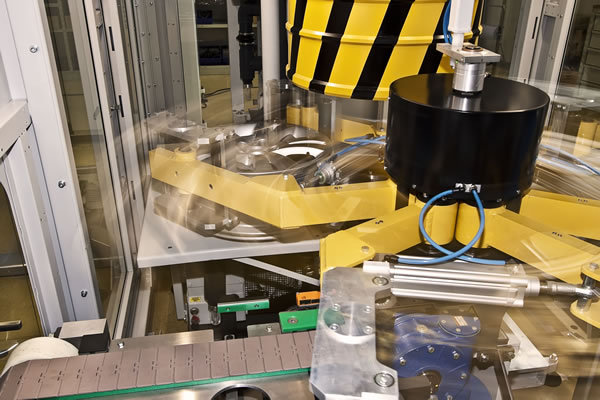

For your quality assurance as manufacturer of aluminum wheels, we deliver a fully automatic machine for the testing of wheels.

The Leak Tester

We developed a fully automatic machine for leak testing of aluminum wheels for the automotive applications. The mass spectrometer test with test gas is used as measurement method. The test gas helium is recovered with a fully automatic recovery system. Our leak testers are used by all leading wheel manufacturers to meet the high quality requirements of the automotive OEM industry.

- Leak Rate: Range 10E-4 ccm/sec

- Cycle Time: 200 parts/hour

- Double Station Tester: 400 Parts/hour

- Test piece volume: 30 to 50 liter

- Test Pressure: 1 to 4 bar

- Test Gas: Helium-Air

Test Piece

The test object is the actual aluminum rim. It is tested if the rim is capable of air-tightening the tire, which is put onto the rim later. We simulate the tire with our special sealing tools in our testing device and measure the test gas flow coming through the test piece (the rim). For this, the test gas is admitted to the outside of the rim and a vacuum is created within the rim.

- Leak Rate: Range 10E-4 ccm/sec

- Cycle Time: 200 parts/hour

- Double Station Tester: 400 Parts/hour

- Test piece volume: 30 to 50 liter

- Test Pressure: 1 to 4 bar

- Test Gas: Helium-Air

Our References

- almost all OEM in wheel manufacturing

Your Advantages

- State-of-the-Art Fabricating Machinery

- Fabrication based on your Samples, Instructions or Drawings

- Reliable and High Quality Production

- Quick Processing